Vacuum circular section die sets for IR spectroscopy and XRF spectrometry

Designation

Vacuum die sets are used when it is necessary to remove water vapors from a sample, in particular, during FTIR spectroscopy and production of KBr pellets. Also vacuuming during pressing is used for equal distribution of powder in matrix and air removal from sample during X-ray fluorescence analysis (RSFA or XRF).

The diameter of the obtained pellet depends on the manufacturer and the model of FTIR or X-ray spectrometer on which the analysis is conducted.

Typically, the diameters of the required pelleted samples are standard (see table 1), but it is possible to manufacture die sets of any diameter, a multiple of 0.1 mm.

Table 1

| Standard gages (mm) | 3 | 5 | 10 | 12 | 13 | 15 | 20 | 25 | 30 | 32 | 40 | |

| Limit operating load (tons) | 0,4 | 1 | 4 | 6 | 7 | 9 | 16 | 24 | 35 | 40 | 60 | |

| Recommended press models |

|

|||||||||||

|

|

||||||||||||

Advantages

- The process of pressing takes place directly between the stopper and the pressing punch without using intermediate anvils that significantly reduces the sample preparation time.

- Air extraction occurs across the all formative matrix that provides an equal distribution of the pressing material between the stopper and the punch.

- Made of durable tool steel. Hardness 60 HRC.

- Does not “infect” the sample (does not add its own material).

- Work surface grinding (Ra0.08) provides an ideal sample surface and eliminates sample sticking on the ends of the punches.

- Die set design ensures the accurate removal of the finished sample.

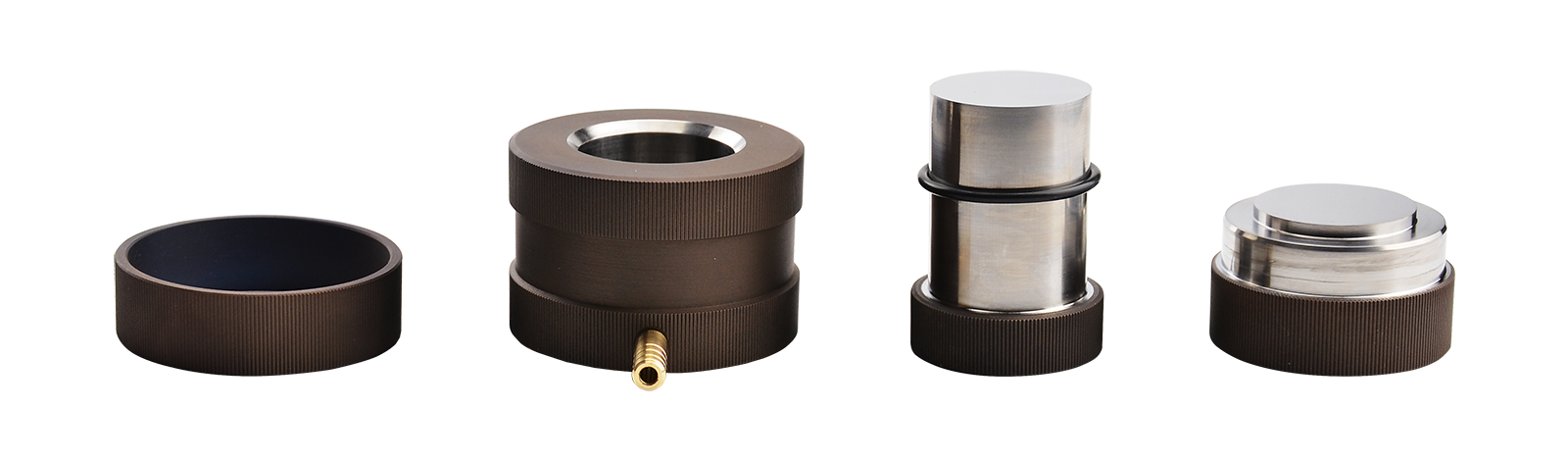

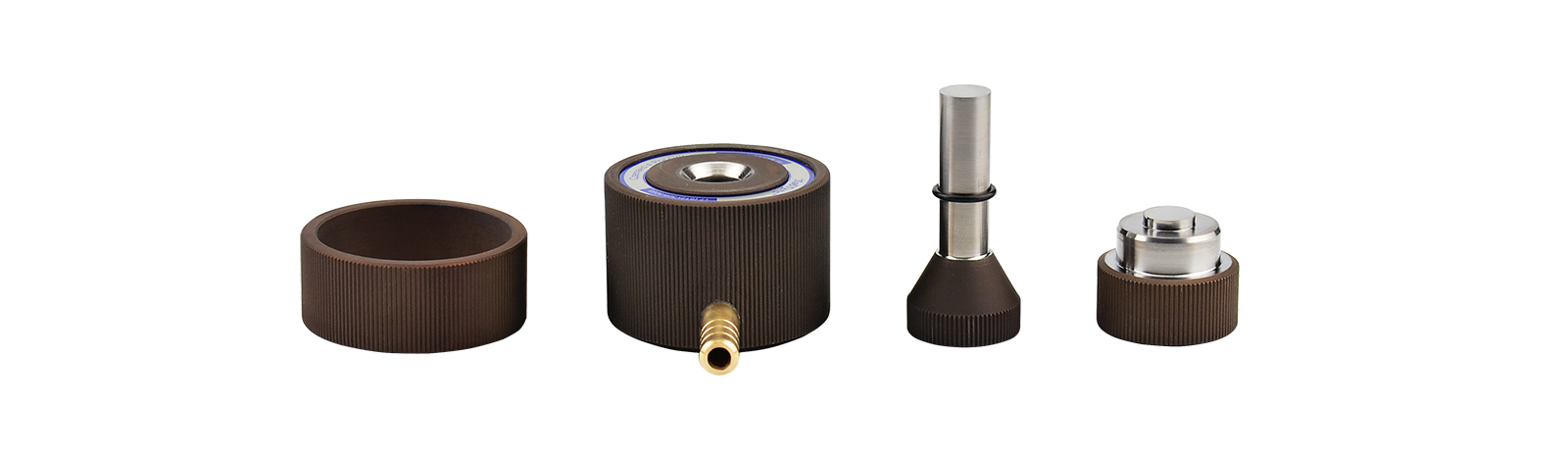

Supply package

- matrix;

- stopper;

- flat face punch;

- punch with figured end to form bonding substrates for die sets used in sample preparation for RSFA (XRF) spectrometry;

- ring or lid for sample extraction;

- an additional set of O-shaped rubber rings;

- instruction manual.

Get a quote